Here you’ll find answers to the most common questions about post-processing at Bergs Mekaniska.

At Bergs Mekaniska, you can always expect:

✔ Top quality

✔ Customer focus

✔ Large inventory

✔ Well-equipped machinery

Take the next step – fill in the form and we will get back to you as soon as we can.

At Bergs Mekaniska, it’s not just about cutting the right shape – it’s about delivering finished components that meet high demands on function, fit and finish. That’s why we offer meticulous post-processing of cut parts, tailored to your specific requirements.

We make sure every part is ready for assembly, surface treatment or further use. With long experience and modern equipment, we guarantee a final finish with high precision and quality.

Post-processing is crucial to make sure a product can be used directly in production or final assembly without issues. It reduces the risk of fit problems, improves durability, and ensures that your components meet a high standard – every time.

We tailor the post-processing to the industry, tolerance requirements and intended function. Whether it’s single custom parts or larger series, our goal is always the same: finished products of the highest quality.

Feel free to contact us to discuss the right post-processing for your parts!

Here you’ll find answers to the most common questions about post-processing at Bergs Mekaniska.

Post-processing is the process of refining a cut part through, for example, grinding, deburring, drilling or tapping in order to achieve the desired shape, function and surface finish.

Post-processing ensures that components obtain the correct dimensions, smooth edges and functional properties, making them ready for further assembly or use.

We offer, among other things, deburring, edge breaking, grinding, drilling, milling, tapping and inspection – all based on your specific requirements.

Yes, we have procedures for quality control and measurement to ensure that all parts meet your requirements and industry standards.

In some cases, yes – contact us and we will see if we can help you with post-processing of existing components.

Additional costs for post-processing depend on the scope and requirements. We offer fast and cost-effective solutions with clear quotation documentation.

Absolutely! We adapt both the machining method and the finish depending on whether you work in, for example, design, industry, automotive or mining.

Yes! Our goal is to deliver complete components that are ready to be used immediately, without you having to spend time on additional processing.

We have a multitasking machine and milling machine that allow us to machine parts with tight tolerances.

Drilling is used to create or enlarge a hole in the material.

We can handle both small and large diameters.

The most common components we produce with threads are screws and nuts, but we also make threads on all kinds of parts.

During bending we form the workpiece to the exact angle and radius specified in the design.

We can bend sheet metal products for construction (studs and other light sheet profiles) as well as small sheet metal parts used in industrial components. We also bend heavier parts, such as components for buckets mounted on wheel loaders and excavators.

Two Ursviken press brakes, 640 tons.

One Ursviken press brake, 150 tons.

We roll both large and thick parts in all materials, and both one-off pieces and series production are no problem.

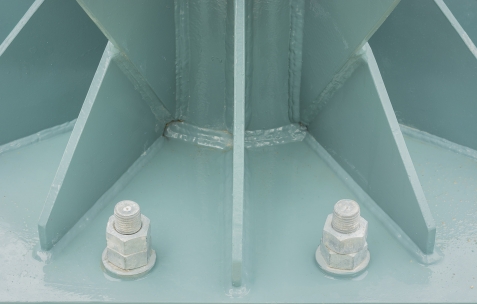

Joint preparation is required for a perfect welding result and makes it easy to weld directly on site.

It saves time for our customers, who don’t have to correct the joints.

We remove irregularities and clean the surface to make welding easier.

A blasted surface provides the best base.

Blasting effectively removes rust, dirt, paint and various coatings.

It is also an efficient pre-treatment before painting and other surface treatments.

By blasting, a fine texture is created on the surface which improves adhesion and increases the quality and service life of the surface treatment.

We can arrange galvanizing for all parts or products according to your requirements.

We can arrange painting of all parts or products according to your requirements.